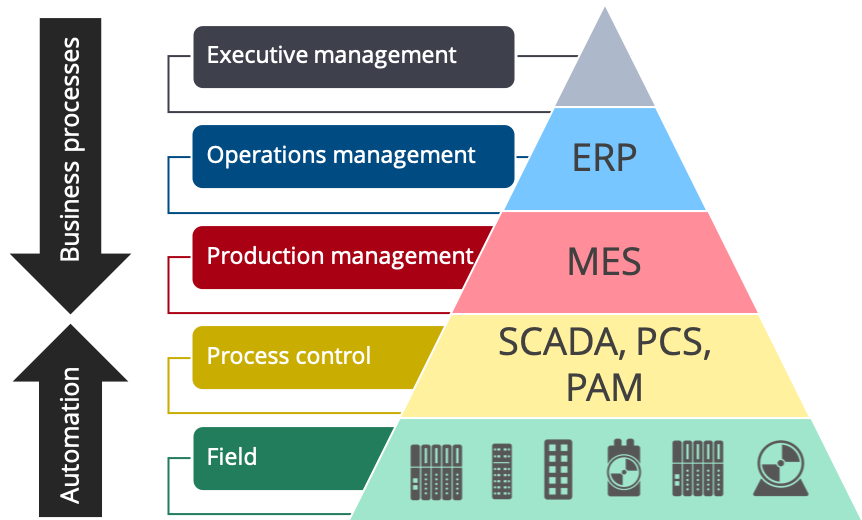

As the main feature within our supervisory and control system, SCA provides integration with the information system of the company (MES, ERP).

During the year, our expert team was develop a special software module for managing recipes, raw materials, orders and tracking statistics.

Thanks to the automated mode of operation of the factory, a minimum number of employees is required to manage and control production.

Fodder factories consist of the following technological units:

- Input and storage of raw materials,

- Grinding,

- Dosing and weighing of individual components,

- Adding oil, fat or molasses,

- Pelletizing,

- Extrusion,

- Mixing,

- Packaging and storage of finished products.

For each technological unit, we are able to apply previous experiences, but also to recognize and apply innovations, so that the end user provides a quality final product for further distribution.